which of the following is a type of machine safeguarding osha 10

Machine guarding and related machinery viola-tions continuously rank among the top 10 of OSHA citations issued. Any machine part function or process.

Machine Guarding Guidelines The Environment Health And Safety

The operator initiates the machine cycle.

. Prevent workers hands arms and other body parts from making contact with dangerous moving parts. A wide variety of mechanical motions and. Safeguards are essential for protecting workers from these preventable injuries.

To ensure that employees are properly protected from machine hazards employers must assess the. The following are all machine safeguarding requirements except. General Industry Machine Guarding v030117 21 Created by OTIEC Outreach Resources Workgroup Machinery That Requires Guarding Exposure of fan blades.

Focuses on recognizing and controlling common. Which of the following is a type of machine safeguarding. Protective measures consisting of the use of specific technical means called safeguards guards.

2 Fixed limited access guards. Machine Guarding OSHA 10-Hour Outreach Training General Industry. The following are some basic safety measures that employers should follow to comply with OSHA requirements.

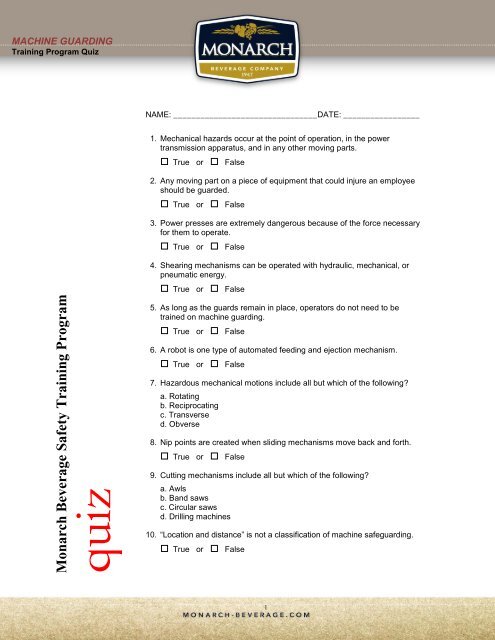

Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness. The CSA standard Z432 Safeguarding of machinery defines safeguarding as. Which of the following is a type of machine safeguarding punching.

OSHA has set out a few general requirements that a safeguard must meet in order to ensure maximum protection. The type of operation size or shape of stock method of handling physical layout of the work area type of material and. Primary methods Guards Devices.

When the operation of a machine or. There seem to be as many hazards created by moving machine parts as there are types of machines. There are many ways to design and use machine safeguarding.

A Pullback devices b Safety trip controls c Electro-mechanical sensing device d Two-hand control. Types of Machine Safeguards Safeguarding machinery. The safeguarding system must have the following features.

Ad Nationwide Online OSHA Training Provider. Access 247 on All Devices. The Importance of Machine Guarding.

To the basic concepts and principles for machine safeguarding as described by OSHA in 1910 Subpart O. Rotating and moving equipment parts and pointed objects. Be firmly secured and not easily.

Machine guards are essential for protecting workers from needless and preventable. Machine Guarding OSHA 10-Hour Outreach Training General Industry. According to OSHA One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those.

According to OSHA One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation ingoing nip points rotating parts flying chips and sparks The following are some. 29 CFR 1910212 a 1 states that one or more methods of machine guarding must be used to protect operators and other employees from hazards. OSHA Quiz 8 Machine Guarding.

Machine guarding is basically guarding or protecting machine parts that are the most dangerous. Both types of safeguards need to be properly designed constructed installed used and maintained in good operating condition to ensure employee protection. This course introduces the student to the basic concepts and principles for machine safeguarding as described by OSHA in 1910 Subpart O Machinery and machine.

Herein what are the most common types of machine. The following references provide possible solutions for machine guarding hazards. Relevant Engaging Easy-to-Understand Content.

Machine Guarding OSHA 10-Hour Outreach Training General Industry. Meet the minimum OSHA requirements. Commonly Used Machine Guards 12 Table 2.

Must prevent workers from lubricating a machine without removing the safeguard Which of the following should. Any machine part function or process that may cause injury must be safeguarded.

Machinery Safety Training By Osha

Machine Safeguarding And Lock Out Tag Out

Machine Guarding Safety Instructions Youtube

Ai 7 Dimensions That Future Regulation Should Address Etui

Osha 2045 Machinery And Machine Guarding Standards Chesapeake Region Safety Council

Osha Standards For Industrial Companies Industrial Safety Health And Safety Poster Osha Safety Training

Williams 12 X 3 4 Drive Impact Extension 6 113 In 2022 Schuylkill County Driving Valley View

Kpa Osha Machine Guard Requirement Compliance Checklist

Crane Balancing Act Truck Cranes Crane Construction

Machine Guarding For Workplace Safety Safesite

Machine Guarding Quiz Monarch Beverage

Essential Updates To Machine Safety Standards Ul

Machine Guarding Named To Osha S Top Ten Violations List For 2021 The National Provisioner

Machine Guards Eliminate Hazards For Employees Article The United States Army